در حال حاضر محصولی در سبد خرید شما وجود ندارد.

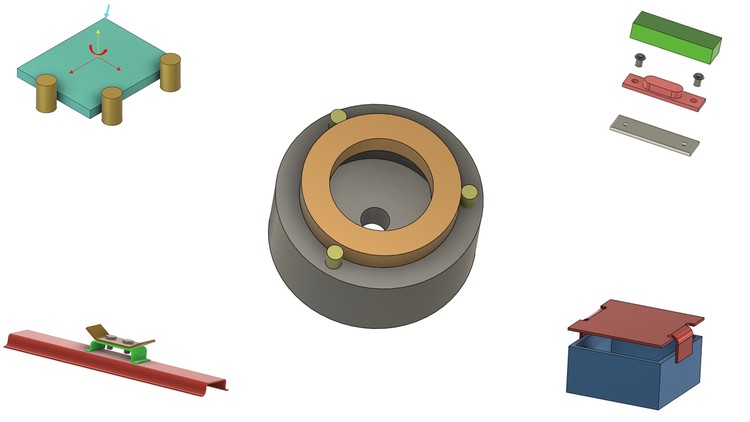

Learn about the best practices in designing mechanical systems for assembly and design with optimal constraints

در این روش نیاز به افزودن محصول به سبد خرید و تکمیل اطلاعات نیست و شما پس از وارد کردن ایمیل خود و طی کردن مراحل پرداخت لینک های دریافت محصولات را در ایمیل خود دریافت خواهید کرد.

✨ تا ۷۰% تخفیف با شارژ کیف پول 🎁

مشاهده پلن ها